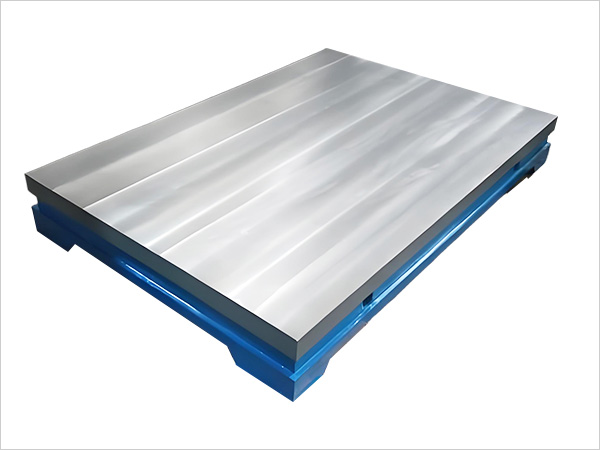

Application Of Cast Iron Surface Panel: Used As A Flat Reference Measuring Tool For Workpiece And Equipment Inspection, Marking, Assembly, Welding, Assembling, And Riveting

Cast Iron Surface Panel Material: High-strength Cast Iron HT200-300, Cast Steel

Production Process Of Cast Iron Surface Panel: The Working Surface Adopts Scraping Process, With An Accuracy Of Level 1.2.3 V-grooves, T-grooves, U-grooves, Dovetail Grooves, Circular Holes, Long Holes, Etc. Can Be Machined On The Working Surface

Cast Iron Surface Panel Blank: Make Drawings According To Technical Requirements, Make Wood Shapes According To Drawings, Mix Ingredients, Shape, Dry, Cast, Sand, Clean, And Inspect Various Parts Of The Blank; Mechanical Processing: Visual Inspection And Marking, Workpiece On Machine Tool, Processing, Inspection, Tempering; Process According To The Drawing Requirements And Send To The Inspection Department For Inspection; Appearance Treatment, Painting, Packaging

Selection Of Accessories For Cast Iron Surface Panels: Mainly The Selection Of Brackets, Which Are Made Of Square Steel And Angle Iron With A Wall Thickness Of 1.5-2mm. The Welding Density And Structure Should Be Reasonable, And The Adjusting Bolts Should Rotate Smoothly.

Installation And Debugging: Generally, A Frame Level Is Used To Level It First, And Then An Optical Or Electronic Image Level Is Used To Measure The Flatness Error Again. If There Are Any Problems, The Cast Iron Platform Manufacturer Can Be Requested To Scrape And Restore The Accuracy On Site.

Packaging Requirements: Mainly Wooden Packaging, Try To Use Thick Wood To Cover The Working Surface On The Platform, And Sometimes Do Fully Enclosed Packaging. Rust Prevention Measures Should Be Taken For The Working Surface Of The Platform Before Packaging

Production Period: 27-30 Days

Specification: Customizable

Specifications (Mm) | Accuracy Class ( μm) | |||

0 | One | Two | Three | |

100 × 100 | Four | Eight | Sixteen | |

200 × 100 | Five | Ten | Twenty | |

200 × 200 | Five | Ten | Twenty | |

300 × 200 | Six | Twelve | Twenty-four | |

300 × 300 | Six | Twelve | Twenty-four | |

400 × 300 | Six | Twelve | Twenty-four | |

400 × 400 | Six | Twelve | Twenty-four | |

500 × 400 | Six | Twelve | Twenty-four | |

600 × 400 | Seven | Fourteen | Twenty-eight | |

600 × 500 | Seven | Fourteen | Twenty-eight | |

800 × 400 | Eight | Sixteen | Thirty-two | Eighty |

800 × 600 | Eight | Sixteen | Thirty-two | Eighty |

900 × 600 | Eight | Sixteen | Thirty-two | Eighty |

1000 × 750 | Eighteen | Thirty-six | Ninety | |

1000 × 1000 | Twenty | Thirty-nine | Ninety-six | |

1200 × 1000 | Twenty | Thirty-nine | Ninety-six | |

1500 × 1000 | Twenty-four | Forty-eight | One Hundred And Twenty | |

2000 × 1000 | Twenty-six | Fifty-two | One Hundred And Twenty-nine | |

2000 × 1500 | Fifty-six | One Hundred And Forty | ||

2000 × 2000 | Sixty | One Hundred And Fifty-two | Two Hundred And Thirty | |

3000 × 1000 | One Hundred And Sixty-eight | Two Hundred And Forty-eight | ||

3000 × 1500 | One Hundred And Seventy-four | Two Hundred And Fifty-four | ||

3000 × 2000 | One Hundred And Eighty-four | Two Hundred And Seventy-five | ||

4000 × 2000 | Two Hundred And Nineteen | Three Hundred And Ten | ||

4000 × 3000 | Two Hundred And Forty | Three Hundred And Sixty | ||

6000 × 3000 | Three Hundred And Eight | Four Hundred And Sixty | ||

Payment Method: 30% Advance Payment, Take Pictures And Videos For The Customer Before Shipment, And The Customer Pays The Remaining Balance

Transportation Methods: Sea Freight, Land Freight

Made In China, Welcome To The Factory

Factory Direct Sales Savings: By Purchasing Directly From Our Factory, You Can Save A Significant Amount Of Costs. Our Streamlined Supply Chain Eliminates Intermediaries, Allowing Us To Offer Competitive Prices Without Compromising Quality.

Batch Order Discount: For Large Projects Or Industrial Applications, We Offer Significant Discounts For Bulk Orders. Please Contact Us To Discuss Your Specific Requirements And Obtain A Customized Quotation That Is Suitable For Your Budget And Project Scale