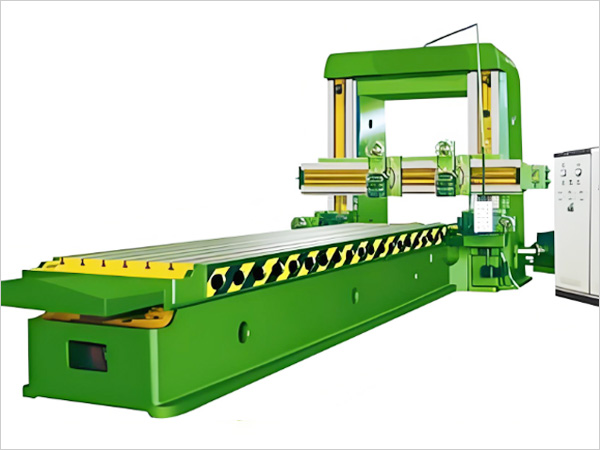

B20 SeriesPlanerIt Is A New Type Of Machine Tool Developed On The Basis Of The Traditional Gantry Planer, Which Combines The Advantages Of The Machine Tool And Is Equipped With Electrical Appliances To Upgrade The Electromechanical Control Technology. Equipped With Milling Heads And Grinding Heads, It Can Achieve Functions Such As Planing, Milling, Grinding, Drilling, And Countersunking. Equipped With Right Angle Accessory Milling Heads, It Can Clamp Workpieces In One Go, Achieve Five Sided Machining, And Have Multiple Uses, Improving The Machining Quality And Production Efficiency Of Workpieces.

This Series Of Machine Tools Is The Basic Machine Tool For Longmen Milling And Grinding Machines. At The Same Time Of Development, Milling And Grinding Functions Were Reserved, And Milling And Grinding Heads Can Be Installed At Any Time To Meet Different Processing Requirements.

Main Structural Performance And Characteristics:

The Main Components Of The Machine Tool, Including The Bed, Worktable, Left And Right Columns, Crossbeam, Gantry Top, And Connecting Beam, Are All Made Of Resin Sand Molding And High Alloy Wear-resistant Cast Iron Casting. They Undergo Heat Aging Treatment, Vibration Aging Treatment, Rough Machining, Vibration Aging Treatment, And Precision Machining To Eliminate Negative Stress On The Machine Parts And Maintain Stable Performance.

The Horizontal Beam Lifting And Positioning Is Mechanically Or Hydraulically Locked, With Accurate Positioning.

The Horizontal Feed Of The Crossbeam Vertical Tool Holder (vertical Milling Head) And The Vertical Feed Of The Side Tool Holder (side Milling Head) Are Both Controlled By AC Servo, With Intermittent And Continuous Stepless Feed.

The Surface Of The Machine Tool Guide Rail Is Subjected To Audio Quenching Or Point Contact Hardening Treatment And Precision Grinding.

★ The Surface Of The Workbench Guide Rail Is Bonded With A High Wear Resistance Guide Rail Pair.

★ Lubrication Realizes Adjustable Semi Static Pressure Of Oil Float, Saving Operating Power And Maintaining The Accuracy Of Guide Rail For A Long Time.

The Main Drive Adopts A Self-developed Four Speed Multifunctional Gearbox For Planing, Milling, And Grinding, Controlled By A Variable Frequency And Stepless Speed Control System, Achieving Low Speed And High Torque, Enabling Fast Planing, Low-speed Milling, And Grinding, And Smooth Operation.

The Electromechanical Control System Adopts Programmable PLC Central Processing Unit And Intelligent Power Amplifier, Digital AC Servo Control Technology (IMS Series Controller), To Achieve High-precision Servo Control Of Three-phase AC Asynchronous Motors.

★ Workbench Operation Equipment; YSK AC Servo Control (variable Frequency) Motor Achieves Low-speed, Low-energy, And High Torque Drive (saving 30-40% Energy Compared To DC European Motor Units), With A 2500 Line Encoder That Can Achieve Operation Control.

★ The Workbench Is Set To Touch Screen Settings, And All Feeds Are Suspended Button Stations, Making It Convenient.