Machine ToolWedged Pad IronIt Is An Important Component Used For The Installation And Adjustment Of Mechanical Equipment, Widely Used In Multiple Industries.

Machine Tool Inclined Pad Iron Has Important Applications In Various Industries Such As Mining, Dust Removal, Metallurgy, Railway, Military, Petroleum, Petrochemical, Machine Tool, Mechanical Equipment Installation And Commissioning, And Mechanical Processing. It Is Mainly Used For Horizontal And Parallel Adjustment Of Equipment, Ensuring That The Equipment Does Not Vibrate Or Tilt During Operation, Thereby Ensuring Good Machine Operation, Reducing Wear And Tear, And Ensuring Equipment Safety.

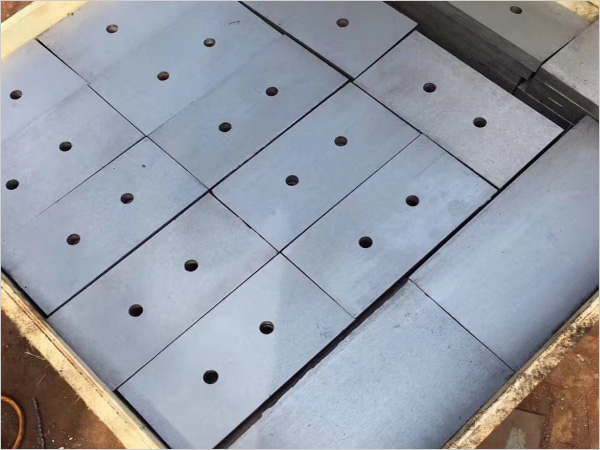

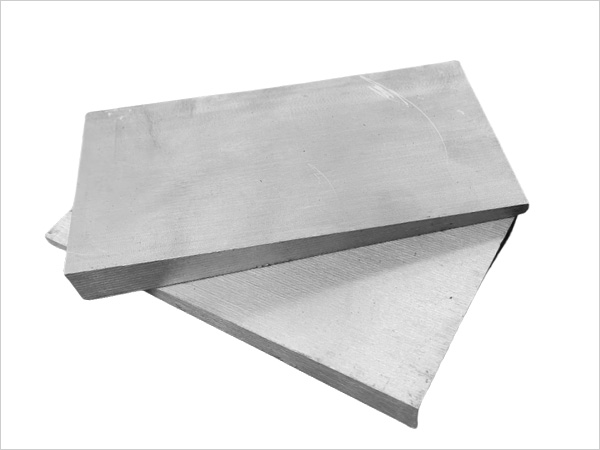

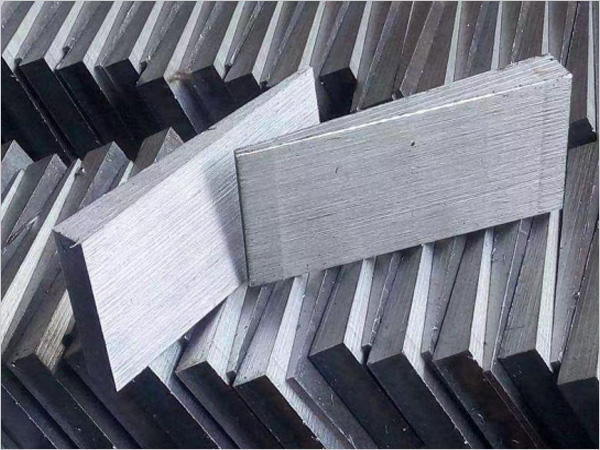

There Are Many Types Of Inclined Shims For Machine Tools, Which Can Be Divided Into Cast Inclined Shims, Cast Iron Inclined Shims (such As HT200, HT250, Etc.), Steel Inclined Shims (such As Q235), Forged Inclined Shims, Ductile Iron Inclined Shims, Etc. According To Their Materials; According To The Structure, It Can Be Divided Into Flat Inclined Pad Iron, Inclined Pad Iron, Square Inclined Pad Iron, Stepped Inclined Pad Iron, Etc. These Inclined Pad Irons Generally Do Not Have Specific Specifications And Are Usually Customized And Processed According To Equipment Weight And Design Drawings, But There Are Also Some Commonly Used Specifications And Sizes To Choose From.

When Using Machine Tool Inclined Shims, It Is Necessary To Select Suitable Materials And Specifications According To The Needs Of The Equipment, And Perform Precise Installation And Adjustment. The Use Of Inclined Pad Iron Is Very Simple, Convenient, And Fast, Which Can Save Costs, And Welding Is Also Very Convenient. At The Same Time, The Inclined Pad Iron Also Has The Characteristics Of Durability And Resistance To Deformation, Which Can Ensure The Long-term Stable Operation Of The Equipment.

In Addition, Attention Should Be Paid To Preventing Rust When Storing The Inclined Pad Iron Of The Machine Tool To Ensure Its Service Life And Performance. Overall, The Inclined Shim Of Machine Tools Is An Indispensable Part Of Industrial Production, Providing Solid Support For The Normal Operation Of Equipment.