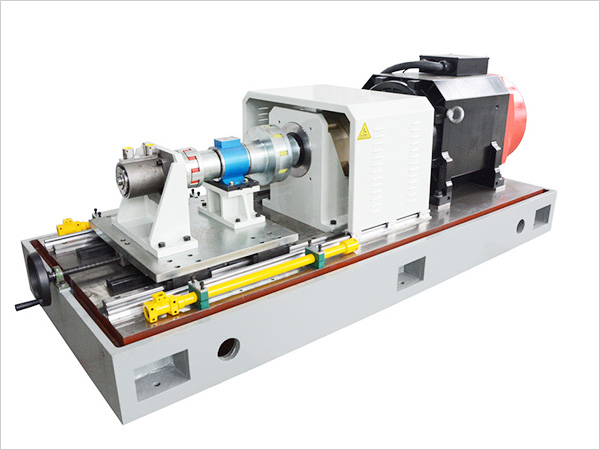

Cast Iron T-groove Test Bench/cast Iron T-groove Machine Test Bench; Suitable For Various Industries Such As Automotive And Heavy Engineering, Including Engine Testing, Electric Motor Testing, Generator Testing, Transmission Testing, Steering System Testing, And Component Testing.

The Test Bench Is Fully Manufactured Internally And Has World-class Manufacturing Facilities Equipped With CNC Machines, From Design, Casting, Processing To Precision Machining And Packaging. Ensure Product Quality, Comply With International Standards Such As IS And DIN, Have Core Wire And Rib Structure, Cast Iron Grades Ranging From FG200 (according To IS210) Or GG-20 To FG-30 (or Higher) With A Hardness Of Up To 160BHN

Basic Features:

Profile: Usually Provides T-shaped Groove Sizes Of 14.18.22.28.36 Or 42mm In Accordance With IS: 2013/DIN/DIN650, With Tolerances Ranging From H12 To H7. Holes, Square Grooves, Guide Grooves Or Other Profiles Can Be Provided On The Top And Sides According To Customer Requirements

Installation: According To The Installation And Testing Platform, There Are Mainly Two Types That Can Be Manufactured

(1) Equipped With Leveling And Anchoring Devices, It Can Be Directly Installed On The Floor Or Seismic Quality Foundation.

(2) The Bottom Of The Test Bench Is Equipped With Organic Processing Pads, Which Can Be Installed On Air Springs Or Mechanical Springs.

Arrange Professional Personnel To Install And Debug On Site Achieve Customer Satisfaction

Stress Relief: The Test Bench Is Manufactured Using Castings That Have Undergone Rough Machining To Appropriately Relieve Stress, In Order To Prevent Deformation

Height: The Test Bench Should Be Manufactured According To The Application And Static And Dynamic Loads To Various Heights Of 150.175, 250.300, 350.400, And 500mm

Plane Accuracy: According To DIN-876 Or IS-10602 Levels 1.2.3.

Surface Size: CNC Surface Treatment Or Manual Scraping Surface Treatment Can Be Provided According To Requirements

Other Sizes And Combinations Can Be Manufactured According To Requirements.

Large Sizes Can Be Manufactured By Connecting The Boards Along The Sides To Form The Required Total Area

The Production Process Involves Drawing According To Technical Requirements, Making Wood Shapes, Batching, Shaping, Drying, Casting, Sanding, Cleaning, And Inspecting Various Parts Of The Blank According To The Drawings; Mechanical Processing: Visual Inspection And Marking, Workpiece On Machine Tool, Processing, Inspection, Tempering; Process According To The Drawing Requirements And Send To The Inspection Department For Inspection; Appearance Treatment, Painting, Packaging

Dimensions In Millimeters (length X Width)

1000X1000 | 3000x1500 | 4000x2500 |

1500x1000 | 3000x2000 | 4000x3000 |

1500x1500 | 3000x2500 | 5000x1500 |

2000x1000 | 3000x3000 | 5000x2000 |

2000x1500 | 3500x1500 | 5000x2500 |

2000x2000 | 3500x2000 | 5000X3000 |

2500x1000 | 3500x2500 | 6000X1500 |

2500x1500 | 3500x3000 | 6000X2000 |

2500x2000 | 4000x1000 | 6000X2500 |

2500x2500 | 4000x1500 | 7000X2000 |

3000x1000 | 4000x2000 | 7000X2500 |