Application Scenarios Of Rain Cover For Belt Conveyor

1. Mining: In Mines, Belt Conveyors Need To Be Used For Open-pit Transportation Of Ore And Other Materials. The Installation Of Our Rain Cover Can Ensure That The Materials Are Not Excessively Wet Even In Rainstorm, And Avoid The Influence Of The High Water Content Of Materials On The Subsequent Processing Process. For Example, When Ore Is Crushed And Screened, The Equipment Can Operate Efficiently Only When The Water Content Is Appropriate.

2. Port Terminal: The Port Frequently Handles Various Types Of Goods, And Belt Conveyors Operate Continuously. Rainproof Covers Can Prevent Rainwater From Wetting Goods, Such As Coal, Which May Cause Weight Increase And Quality Degradation. They Can Also Prevent Materials From Scattering Due To Rainwater Erosion And Maintain The Cleanliness Of The Port Operation Area.

3. Construction Site: Belt Conveyors Are Used On Construction Sites To Transport Building Materials Such As Sand, Gravel, Cement, Etc. Rain Cover Can Prevent Cement From Clumping And Failing When It Comes Into Contact With Water, Ensure Stable Moisture Content Of Sand And Gravel, Facilitate Precise Mixing Of Concrete, And Ensure The Quality Of Construction Projects.

Function

Effective Rainproof: Made Of High-quality Rainproof Materials, Such As Durable Color Steel Plates, It Has Excellent Waterproof Performance And Is Tightly Covered On The Belt Conveyor, Which Can Block Rainwater In All Directions And Ensure That The Conveyor And Materials Are Not Wet.

Protection Equipment: Long Term Erosion By Rainwater Can Cause Rust On The Metal Parts Of The Conveyor, Shortening The Lifespan Of The Equipment. Rain Covers Can Isolate Rainwater From Contact With Equipment, Reduce The Risk Of Rust And Corrosion, Lower Maintenance Costs, Extend The Overall Service Life Of Conveyors, Ensure Stable Operation Of Equipment, And Reduce Production Downtime Caused By Equipment Failures.

Prevent Material Loss: During Rain, If Not Protected, The Impact Of Rainwater May Cause Materials On The Belt To Spill. Rain Cover Can Block The Impact Of Rainwater, Prevent Materials From Being Washed Away, Reduce Material Loss, And Save You Costs. Pay Attention To Installing The Processed Boards Onto The Support Frame In The Designed Order. Use Self Tapping Screws Or Rivets To Connect And Fix The Board To The Frame, Paying Attention To The Tight Splicing Between The Boards To Avoid Gaps.

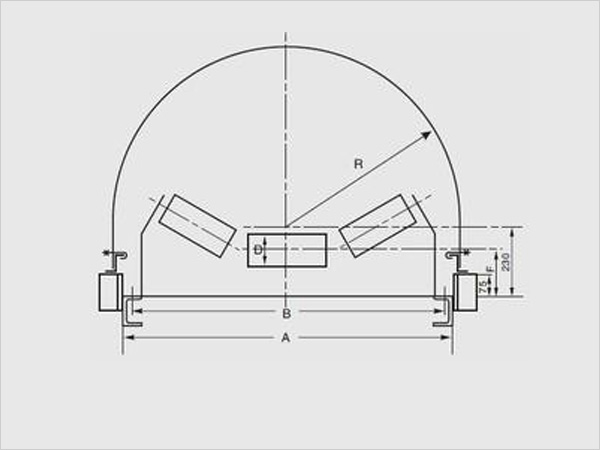

Method For Measuring The Size Of The Conveyor Hood:

1. Width: Use A Tape Measure To Measure Horizontally At The Widest Point Of The Belt To Obtain The Width Of The Belt. This Is The Key Basis For Designing The Internal Width Of The Dust Cover, Ensuring That The Dust Cover Can Completely Cover The Belt. Generally, The Internal Width Of The Dust Cover Should Be 5-10 Centimeters Wider Than The Belt To Prevent Dust From Rising Out When Materials Overflow.

-Length: Measure The Length Of The Belt Between The Head And Tail Ends Of The Conveyor Along The Direction Of Belt Movement, Providing Reference For The Length Of The Dust Cover. However, Considering That The Conveyor May Have Special Parts Such As Bends And Transitions, The Actual Length Of The Dust Cover Needs To Be Reasonably Extended On This Basis, Generally By 10% -20%, To Ensure Full Stroke Protection.

2. Conveyor Frame:

-Height: Measure Vertically From The Bottom Support Surface Of The Conveyor To The Highest Point At The Top Of The Frame To Understand The Overall Height Of The Frame, In Order To Determine The Height Of The Dust Cover And Ensure Sufficient Space Inside To Accommodate The Operation Of The Belt And Rollers. Usually, The Height Inside The Dust Cover Should Be 15-30 Centimeters Higher Than The Highest Point Of The Frame.

-Width: Measure The Distance Between The Outermost Ends Of The Conveyor Frame On Both Sides, Which Helps Determine The Lateral Dimensions Of The Dust Cover And Ensures That It Can Wrap Around The Frame. Generally, The Outer Width Of The Dust Cover Is 10-20 Centimeters Wider Than The Frame.

3. Roller And Idler:

-Drum Diameter: Measure The Diameter Of Each Drum, And Reserve Appropriate Space For The Dust Cover At The Drum To Avoid Interference. Generally, The Distance Between The Dust Cover And The Edge Of The Drum Should Be Kept At 10-15 Centimeters.

-Roller Spacing And Height: Measure The Distance Between Adjacent Rollers, As Well As The Height From The Top Of The Rollers To The Bottom Of The Frame, Which Helps Determine The Shape And Height Of The Bottom Of The Dust Cover, Ensuring That The Bottom Of The Dust Cover Is Compatible With The Rollers And Does Not Affect Their Rotation.

4. Special Parts:

-Turning Point: If The Conveyor Has A Turning Point, It Is Necessary To Measure The Turning Radius, Angle, And The Length Difference Between The Inside And Outside Of The Belt At The Turning Point. The Dust Cover At The Turning Point Should Be Specially Designed To Ensure A Tight Fit And Not Affect The Turning Of The Belt, Such As Using Bendable Materials Or Segmented Splicing Design.

Conveyor Width

|

R |

A |

W |

L |

H |

BFive Hundred | Four Hundred And Twenty-three | Eight Hundred | Eight Hundred And Forty-six | Nine Hundred And Twenty | Five Hundred And Seventy-three |

BSix Hundred And Fifty | Four Hundred And Ninety-eight | Nine Hundred And Fifty | 12 Hours A Day 6 Days A Week | Nine Hundred And Twenty | Six Hundred And Forty-eight |

BEight Hundred | Five Hundred And Ninety-eight | One Thousand One Hundred And Fifty | One Thousand One Hundred And Ninety-six | Nine Hundred And Twenty | Seven Hundred And Forty-eight |

BOne Thousand | Six Hundred And Ninety-eight | One Thousand Three Hundred And Fifty | One Thousand Three Hundred And Ninety-six | Nine Hundred And Twenty | Eight Hundred And Forty-eight |

BOne Thousand And Two Hundred | Eight Hundred And Three | One Thousand Five Hundred And Seventy | One Thousand Six Hundred And Six | Nine Hundred And Twenty | Nine Hundred And Fifty-three |

BOne Thousand And Four Hundred | Nine Hundred And Twenty-eight | One Thousand Eight Hundred And Ten | One Thousand Eight Hundred And Fifty-six | Nine Hundred And Twenty | One Thousand And Seventy-eight |

BOne Thousand And Six Hundred | One Thousand And Twenty-eight | Two Thousand And Ten | Two Thousand And Fifty-six | Nine Hundred And Twenty | One Thousand One Hundred And Seventy-three |

B1800 | One Thousand One Hundred And Fifty | Two Thousand Two Hundred And Eighty | Two Thousand And Three Hundred | Nine Hundred And Twenty | One Thousand And Three Hundred |

B2000 | One Thousand Two Hundred And Seventy | Two Thousand And Five Hundred | Two Thousand Five Hundred And Forty | Nine Hundred And Twenty | One Thousand Four Hundred And Twenty |

B2200 | One Thousand Four Hundred And Ten | Two Thousand Seven Hundred And Fifty | Two Thousand Eight Hundred And Twenty | Nine Hundred And Twenty | One Thousand Five Hundred And Sixty |

B2400 | One Thousand Five Hundred And Thirty | Three Thousand And Ten | Three Thousand And Sixty | Nine Hundred And Twenty | One Thousand Six Hundred And Eighty |

Installation Instructions For Rain Cover Of Belt Conveyor:

(1) Weld Galvanized Angle Iron And Galvanized Z-shaped Purlins On Both Sides Of The Conveyor Belt Truss, Place The Conveyor Cover On Top, And Then Fix It With Hook Nails This Installation Method Is Sturdy And Durable.

(2) Galvanized Angle Iron Is Welded On Both Sides Of The Conveyor Belt Truss, And The Conveyor Cover And Angle Iron Are Fixed With Drill Tail Wire. Two Installation Methods, Choose The One That Suits Your Own Enterprise

Note: Z-shaped Purlin Is 3 Meters Long, Hook Nail Specification Is M6, Angle Iron Is 30 * 30 * 2, 10 Cm Per Section

Specifications And Colors Can Be Customized, And The Necessary Accessories For Installing The Entire Conveyor Production Line Include Observation Windows; Deviation Switch Box; Heart Regulating Box; Open Accessories; Galvanized Z-shaped Purlins, Galvanized Angle Irons, Hook Nails Or Drill Tail Wires

Chinese Manufacturer, Welcome To The Factory.

Factory Direct Sales Savings: By Purchasing Directly From Our Factory, You Can Save A Significant Amount Of Costs. Our Streamlined Supply Chain Eliminates Intermediaries, Allowing Us To Offer Competitive Prices Without Compromising Quality.

Batch Order Discount: For Large Projects Or Industrial Applications, We Offer Significant Discounts For Bulk Orders. Please Contact Us To Discuss Your Specific Requirements And Obtain A Customized Quotation That Is Suitable For Your Budget And Project Scale