Installing A Rain Cover On The Conveyor Is Meaningful As It Helps Minimize Or Eliminate Serious And Costly Belt Deviation Issues Caused By Moisture Infiltration Into Cracks, And Extends The Service Life Of The Conveyor Belt The Rain Cover Of The Conveyor Is Installed With A Lock Buckle, Which Can Withstand Extreme High Temperatures, Wind, Humidity, And Rainwater For A Long Time. There Are Locking Buckles On Both Sides, Allowing Continuous Access From Either Side Of The Conveyor. The Conveyor Belt Cover Is Made Of Various Optional Materials, Including Galvanized Steel, Pre Painted Steel, Stainless Steel, And Aluminum.

The Rain Cover Of The Conveyor Can Serve As A Protective Barrier Against Harsh Environmental Factors, While Also Protecting Workers From Dust Pollution And Related Maintenance And Cleaning Costs.

When Installing The Best Conveyor Belt Cover, Some Important Factors Need To Be Considered, Such As Durability, Lightweight, And Ease Of Maintenance.

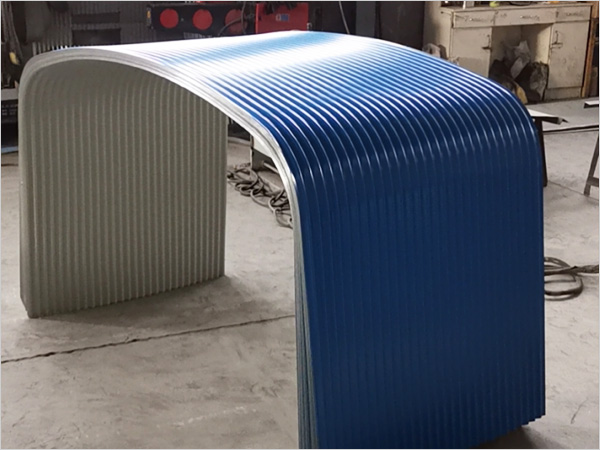

The Color Of The Conveyor Belt Cover Can Be Customized, And The General Stock Includes Blue, Gray, White, And Red

Board Thickness: 0.5mm, 0.6mm, 0.7mm, 0.8mm, 1mm, 1.2mm. The Recommended Thickness Is 1.2mm Because The Surface Of The Lid Is Corrugated, Which Enhances Its Hardness. It Can Be Used For 10-13 Years Without Any Problems

The Cover Plate Can Be Easily Disassembled And Replaced At Any Position For Inspection Of The Conveyor System. We Can Also Make Cover Plates Of Any Size And Equip Them With Different Inspection And Maintenance Openings. We Also Offer Special Cover Plates, Such As Giant Cover Plates, Segmented Arch Cover Plates, And Segmented Cover Plates

The Production Of Conveyor Belt Covers Requires Several Processes Including Plate Selection, Feeding, Pressing, Shearing, Arc Pressing, Lifting, And Packaging To Be Completed. Color Steel Plate With Iron Inside And Baked Paint Outside For Protection

Especially Used In Mines, Quarries, Port Facilities, And Cement Plants.

Cement Industry: Transporting Limestone, Clinker, Cement, Secondary Combustibles, Filtering Dust, Etc.

Chemical Industry: Transporting Granular Materials, Fertilizers, Etc. Recommended Stainless Steel 304 Material

Steel Industry: Transporting Ores.

Power Plants: Transport Coal, Slag, Gypsum, Limestone Powder, Alternative Fuels, Etc.

Waste Recycling: Processing Urban Garbage, Wood, And Sewage Sludge.

Quarry: Mining Gravel And Sand Pits.

Mining Industry: Transportation Of Iron Ore, Copper Ore, Gold Ore, Zinc Ore, Lead Ore, Etc.

Phosphate Mining And Processing: Transporting Phosphate Materials. Recommended Stainless Steel 304 Material

Other Materials: Transportation Of Feed, Grains, Dust, Sawdust, Alumina, Etc.

Specialized Transportation: Handling Hazardous, Contaminated, Dusty, Or Very Light Substances.

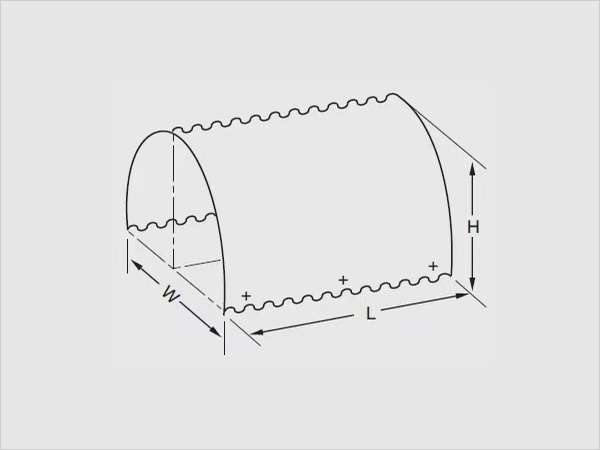

Conveyer BeltCover Size Can Be Customized

Conveyor Width

|

R |

A |

W |

L |

H |

BFive Hundred | Four Hundred And Twenty-three | Eight Hundred | Eight Hundred And Forty-six | Nine Hundred And Twenty | Five Hundred And Seventy-three |

BSix Hundred And Fifty | Four Hundred And Ninety-eight | Nine Hundred And Fifty | 12 Hours A Day 6 Days A Week | Nine Hundred And Twenty | Six Hundred And Forty-eight |

BEight Hundred | Five Hundred And Ninety-eight | One Thousand One Hundred And Fifty | One Thousand One Hundred And Ninety-six | Nine Hundred And Twenty | Seven Hundred And Forty-eight |

BOne Thousand | Six Hundred And Ninety-eight | One Thousand Three Hundred And Fifty | One Thousand Three Hundred And Ninety-six | Nine Hundred And Twenty | Eight Hundred And Forty-eight |

BOne Thousand And Two Hundred | Eight Hundred And Three | One Thousand Five Hundred And Seventy | One Thousand Six Hundred And Six | Nine Hundred And Twenty | Nine Hundred And Fifty-three |

BOne Thousand And Four Hundred | Nine Hundred And Twenty-eight | One Thousand Eight Hundred And Ten | One Thousand Eight Hundred And Fifty-six | Nine Hundred And Twenty | One Thousand And Seventy-eight |

BOne Thousand And Six Hundred | One Thousand And Twenty-eight | Two Thousand And Ten | Two Thousand And Fifty-six | Nine Hundred And Twenty | One Thousand One Hundred And Seventy-three |

B1800 | One Thousand One Hundred And Fifty | Two Thousand Two Hundred And Eighty | Two Thousand And Three Hundred | Nine Hundred And Twenty | One Thousand And Three Hundred |

B2000 | One Thousand Two Hundred And Seventy | Two Thousand And Five Hundred | Two Thousand Five Hundred And Forty | Nine Hundred And Twenty | One Thousand Four Hundred And Twenty |

B2200 | One Thousand Four Hundred And Ten | Two Thousand Seven Hundred And Fifty | Two Thousand Eight Hundred And Twenty | Nine Hundred And Twenty | One Thousand Five Hundred And Sixty |

B2400 | One Thousand Five Hundred And Thirty | Three Thousand And Ten | Three Thousand And Sixty | Nine Hundred And Twenty | One Thousand Six Hundred And Eighty |

Method For Measuring The Size Of The Conveyor Hood:

1. Width: Use A Tape Measure To Measure Horizontally At The Widest Point Of The Belt To Obtain The Width Of The Belt. This Is The Key Basis For Designing The Internal Width Of The Dust Cover, Ensuring That The Dust Cover Can Completely Cover The Belt. Generally, The Internal Width Of The Dust Cover Should Be 5-10 Centimeters Wider Than The Belt To Prevent Dust From Rising Out When Materials Overflow.

-Length: Measure The Length Of The Belt Between The Head And Tail Ends Of The Conveyor Along The Direction Of Belt Movement, Providing Reference For The Length Of The Dust Cover. However, Considering That The Conveyor May Have Special Parts Such As Bends And Transitions, The Actual Length Of The Dust Cover Needs To Be Reasonably Extended On This Basis, Generally By 10% -20%, To Ensure Full Stroke Protection.

2. Conveyor Frame:

-Height: Measure Vertically From The Bottom Support Surface Of The Conveyor To The Highest Point At The Top Of The Frame To Understand The Overall Height Of The Frame, In Order To Determine The Height Of The Dust Cover And Ensure Sufficient Space Inside To Accommodate The Operation Of The Belt And Rollers. Usually, The Height Inside The Dust Cover Should Be 15-30 Centimeters Higher Than The Highest Point Of The Frame.

-Width: Measure The Distance Between The Outermost Ends Of The Conveyor Frame On Both Sides, Which Helps Determine The Lateral Dimensions Of The Dust Cover And Ensures That It Can Wrap Around The Frame. Generally, The Outer Width Of The Dust Cover Is 10-20 Centimeters Wider Than The Frame.

3. Roller And Idler:

-Drum Diameter: Measure The Diameter Of Each Drum, And Reserve Appropriate Space For The Dust Cover At The Drum To Avoid Interference. Generally, The Distance Between The Dust Cover And The Edge Of The Drum Should Be Kept At 10-15 Centimeters.

-Roller Spacing And Height: Measure The Distance Between Adjacent Rollers, As Well As The Height From The Top Of The Rollers To The Bottom Of The Frame, Which Helps Determine The Shape And Height Of The Bottom Of The Dust Cover, Ensuring That The Bottom Of The Dust Cover Is Compatible With The Rollers And Does Not Affect Their Rotation.

4. Special Parts:

-Turning Point: If The Conveyor Has A Turning Point, It Is Necessary To Measure The Turning Radius, Angle, And The Length Difference Between The Inside And Outside Of The Belt At The Turning Point. The Dust Cover At The Turning Point Should Be Specially Designed To Ensure A Tight Fit And Not Affect The Turning Of The Belt, Such As Using Bendable Materials Or Segmented Splicing Design

The Production Period Is Generally One Working Day, And Can Be Expedited

Payment Method: 30% Advance Payment, With Photos Or Videos Taken By The Buyer Before Shipment The Purchaser Shall Pay The Final Payment

Factory Direct Sales Savings: By Purchasing Directly From Our Factory, You Can Save A Significant Amount Of Costs. Our Streamlined Supply Chain Eliminates Intermediaries, Allowing Us To Offer Competitive Prices Without Compromising Quality.

Batch Order Discount: For Large Projects Or Industrial Applications, We Offer Significant Discounts For Bulk Orders. Please Contact Us To Discuss Your Specific Requirements And Obtain A Customized Quotation That Is Suitable For Your Budget And Project Scale

Transport And Packaging Of Conveyor Cover Plates: We Transport Them By Land Or Sea. We Collaborate With Transportation Suppliers Who Are 100% Committed To Our Customer Service Philosophy, Strictly Adhering To Delivery Deadlines And Real-time Order Status Information. We Usually Use Frame Box Packaging And Manufacture According To Each Customer's Requirements